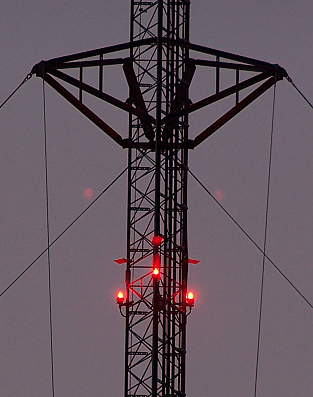

Back in 2017, the Federal Aviation Agency (FAA) and Federal Communications Commission (FCC) re-issued guidance stating non-flashing red lights, such as L-810 side-marker lights, can inadvertently attract birds when illuminated, especially at night. This increases the chances of birds, especially migratory bird, colliding with guy wires, antennas and other tower structural members that are difficult to see during times of low light. They also stated that birds are much less attracted to flashing lights on towers, such as the L-865 white obstruction light and the L-864 red obstruction light.

In the 2015, the FAA published an Advisory Circular with guidance on obstruction lights and maintenance (https://www.faa.gov/documentLibrary/media/Advisory_Circular/AC_70_7460-1L_.pdf) which states the following regarding new lighting and marking standards (see snippets below from the published AC):

Aviation Red Obstruction Lights: Use flashing lights and/or steady-burning lights during nightime.

Medium-Intensity Flashing White Obstruction Lights: May be used during daytime and twilight with automatically selected reduced intensity for nighttime operation. When this system is used on structures 700 feet (213m) AGL or less, other methods of marking and lighting the structure may be omitted. Aviation orange and white paint is always required for daytime marking on structures exceeding 700 feet (213m) AGL.

Inspection, Repair, and Maintenance: To ensure the proper candela output for fixtures with incandescent lamps, the voltage provided to the lamp filament should not vary more than plus or minus three percent of the lamp’s rated voltage. The input voltage should be measured at the closest disconnecting means to the lamp fixture with the lamp operating during the hours of normal operation. (For strobes, the input voltage of the power supplies should be within 10 percent of rated voltage.) Lamps should be replaced after being in operation for approximately 75 percent of their rated life or immediately upon failure. Flashtubes in a light unit should be replaced immediately upon failure, when the peak effective intensity falls below specification limits or when the fixture begins skipping flashes, or at the manufacturer’s recommended intervals. Due to the effects of harsh environments, light fixture lenses should be visually inspected every 24 months, or when the light fixture fails, for ultraviolet (UV) damage, cracks, crazing, dirt buildup, etc., to ensure

the certified light output has not deteriorated. (See Chapter 2 paragraph 2.4 for reporting requirements in case of failure.) Lenses that have cracks, UV damage, crazing, or excessive dirt buildup should be cleaned or replaced.

Is it time for a lighting system inspection or upgrade on your tower? Has it been more than 24 month since your last visually inspection of light fixture lenses, cracks, dirt buildup or rate voltage? The cost of an audit is not high compared to the potential cost savings you may receive by upgrading your lighting system. Plus – you could be saving the lives of many birds!

Pingback: Tower Painting - Masking the Area - Pro Tower Maintenance

Pingback: New Tower Paint - Measuring Dry Film Thickness - Pro Tower Maintenance